Guide, Belt Pulley , Reducer and Servo Motor Sizing

Belt pulley driven is not my favorite method for linear motion. Because this is the drive method with the weakest positioning accuracy. However, if a cheap and high speed method is required, belt pulley is the most suitable method.

I’m using Yaskawa SigmaJunmaSize+ and THK Life Calculator applications for my all calculations.

Target values;

Max Speed: 1000mm/sec

Stroke : 2000mm

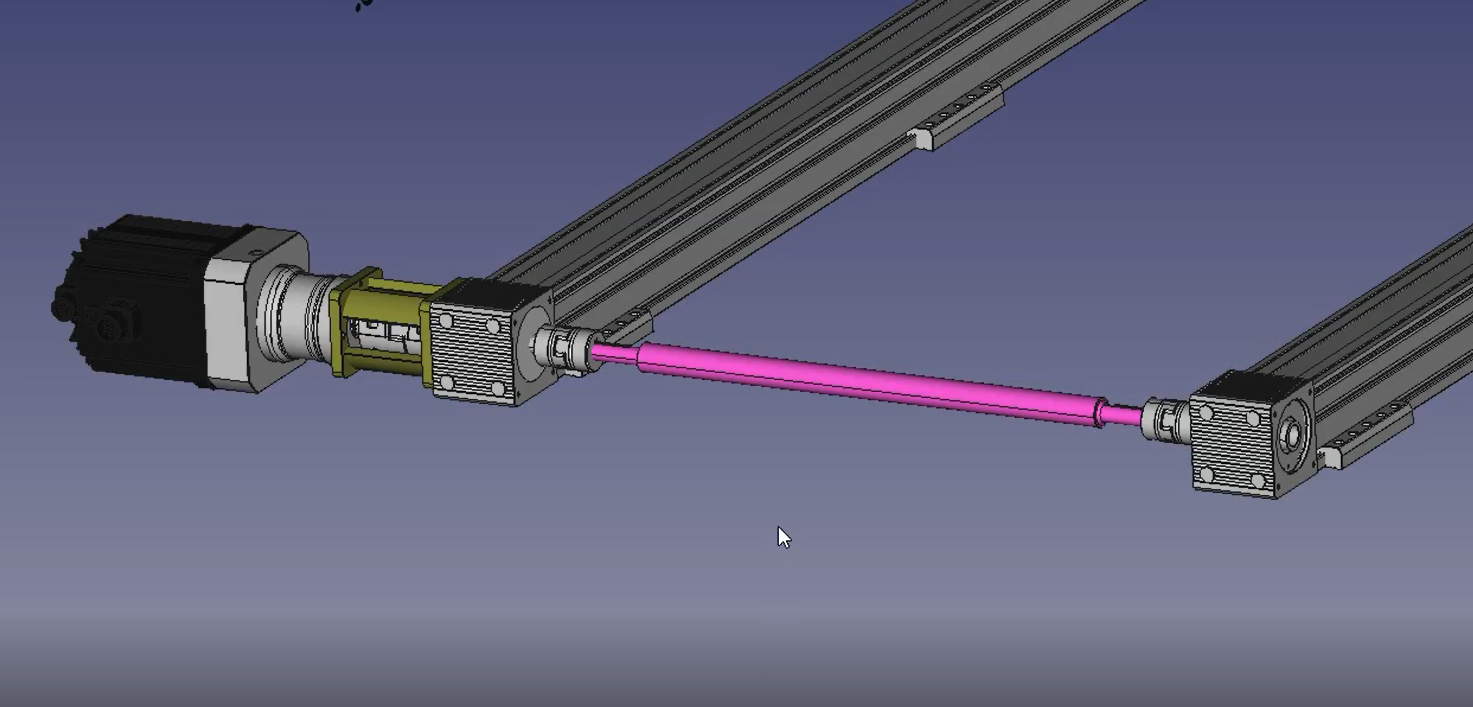

Let’s start by calculating linear guides as usual. This time we have an asymmetric gravity point. There is also a high speed request, which is specified as 1000 mm / second. Therefore, we will use the SHS series, which is more suitable for high speed. You can use these products either externally or assembled in a linear module.

Read more